VR Lip Seal-High Pressure Seal up to 150 Bar

Description of VR Lip Seal

At CV Technik, we are proud to offer high-quality lip seals manufactured by VR Dichtungen GmbH, a trusted name in the industry known for its precision engineering and durable materials. The lip seals are designed to provide reliable sealing for a wide range of applications, ensuring optimal performance and longevity. CV Technik delivers a comprehensive range of VR Lip Seals designed for demanding industrial environments. Available in single or double lip variants and crafted from a wide selection of premium elastomers, our seals can handle pressures up to 150 bar and rotational speeds of up to 40 m/s—all while minimizing friction and shaft wear. This results in longer service life, reduced maintenance, and higher operational efficiency. Select models like our high-durability replacements for traditional oil seals last up to 3x longer than standard alternatives. Our products also meet critical certifications, including EC1935:2004 for food contact and ATEX compliance for explosive zones.

With a focus on quality and innovation, VR lip seals are manufactured to meet the stringent demands of various industries, including automotive, aerospace, manufacturing, and more. VR’s extensive product portfolio includes a variety of lip seal designs, materials, and sizes to suit diverse needs and requirements.

Whether you're looking for standard lip seals or custom solutions tailored to your specific applications, CV Technik has you covered. Explore our comprehensive range of VR lip seals and experience their reliability and efficiency.

Trust CV Technik for all your lip seal needs and discover why we are the preferred choice for professionals across industries. Contact us today to learn more about our lip seal offerings or to place an order.

PRESSURE UP TO 10/15/150 BAR

Function and Working Principle of VR Lip Seal

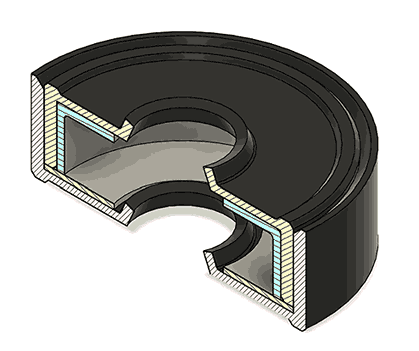

A VR seal is a type of radial shaft seal that uses a flexible rubber membrane supported by a metal ring. It doesn’t need a spring to work. Instead, the rubber sleeve is stretched over a metal support—usually made of stainless steel or another strong material.

The outer part of the seal fits tightly against the housing (non-moving part), while the inner lip touches the rotating shaft. This inner lip is angled and works together with the rubber sleeve. Depending on how the seal is installed and the direction of the pressure from the fluid or gas inside, the sealing lip automatically bends either inward or outward.

This smart design creates a low-friction, energy-efficient seal that lasts a long time—even in demanding applications.

The sealing action is facilitated by the radial and tangential tension exerted on the sleeve body. This tension imparts a spring-like characteristic to the sleeve, ensuring optimal contact between the sealing lip and the rotating shaft. Consequently, the seal effectively mitigates shear stresses induced by rotational motion and adeptly absorbs vibrations and deviations in concentricity, enhancing its operational stability.

Furthermore, the seal's construction minimizes the risk of the sealing lip partially lifting during shaft rotation, thereby mitigating any potential pumping effects. This meticulous design approach ensures the seal's reliability and longevity in demanding applications.

Fundamentals of Lip Sealing

Lip seals form a critical barrier between rotating shafts and fixed housing components. Their role is to retain lubricants and block contaminants (dust, water, chemicals). A spring-loaded lip maintains constant radial force, ensuring tight sealing even under pressure variation or shaft misalignment.

Lubrication Guidelines

For optimal performance:

Use NLGI 1 or NLGI 2 greases

For EPDM, use only silicone-based greases

Avoid synthetic oils unless tested for compatibility

Material Science Behind the Seals

Our lip seals are made from advanced materials, each selected for specific performance needs:

NBR (Nitrile Butadiene Rubber)

Resistant to oil and water

Cost-effective option

Temperature range: -40°C to +108°C

FKM (Fluoroelastomer / Viton)

Excellent chemical resistance

Handles high temperatures

Temperature range: -25°C to +204°C

EPDM (Ethylene Propylene Diene Monomer)

Resistant to UV rays and steam

Safe for use in food applications

Temperature range: -45°C to +130°C

VMQ (Silicone Rubber)

Remains flexible even at very low temperatures

Food-grade quality

Temperature range: -50°C to +200°C

HNBR (Hydrogenated NBR)

Withstands hot water and steam

Suitable for demanding industrial environments

Temperature range: -30°C to +150°C

Material Support Rings & Tolerance Standards

Support rings are available in:

Stainless steel 304 (standard)

Acid-resistant stainless steel

Aluminum or bronze (for high-load or corrosive media)

Advantages of VR Lip Seal

High-pressure applications (10 Bar/15 Bar/ 150 Bar)

Highly suitable for compact space application

No damage to the shaft

Very little scoring due to the springless feature

Very little power loss due to less friction on the shaft surface

Suitable in food, medical and critical sealing application

Extended Lifespan – Proven in some cases to last 8 times longer than conventional seals

Reduced Power Loss – Lower friction = lower energy consumption

Wide Compatibility – Available for gearboxes, motors, pumps, mixers, and more

Hygienic & Hazard-Ready – Suited for food, pharma, and ATEX-rated environments

Applications of VR Lip Seal

All applications where standard oil seal fails to withstand high pressure and also for compact spaces where standard oil seals are difficult to install.

General mechanical engineering (e.g. spindle seals)

Electrical engineering (e.g. motors, rotary encoders)

Medical technology (e.g. very small seals for pumps and instruments)

Pump construction / fan construction (e.g. submersible pumps, centrifugal pumps, axial fans)

Compressor construction (e.g. screw compressors)

Automotive (e.g. climate compressors)

Food machines (e.g. kneading machines)

Agitator and blender and liquidizer technology (e.g. bowl cutter, milk powder machines)

Household machines (e.g. blender, lye pumps, washing machines)

Shipbuilding (e.g. ship shafts)

Gear construction (e.g. high-speed transmission gearing, spur gears)

General vehicle building (e.g. water pump seal, gearbox seal)

Rotary union (e.g. pneumatic controls)

VR Lip Seal Application Industries

-

Automotive Industry

-

Steel and Heavy Engineering

-

Pumps, Motors and Gearboxes

-

Food and Pharma Industry

Product Features of VR Lip Seal

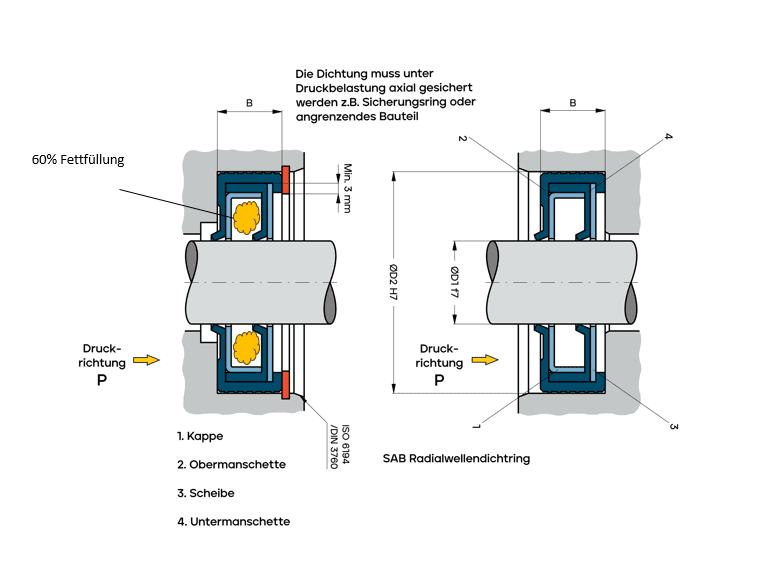

VR seals are built to manage dynamic environments—up to 15 bar in standard versions and 150 bar in reinforced models. The special plain bearing bronze reinforcement in high-pressure seals prevents extrusion, even with shaft clearances as low as 0.02 mm. Seals remain reliable even at 3,000 rpm, making them suitable for compressors, agitators, and high-speed motors.

High-Pressure sealing application

Pressure up to 10 Bar / 15 Bar / 150 Bar

Shaft speed up to Vmax 40 m/s

Materials NBR / FKM / HNBR / EPDM / Silicone or VMQ / Custom

Temperature range -40°C to 220°C

Various profiles are available for different applications

Custom materials and dimensions can be supplied as per your demand

VR Single & Double Lip Configurations

Depending on application and pressure direction, VR seals are offered in:

Single lip: For one-way pressure sealing

Double lip: Dual protection, can act as a grease reservoir

Custom configurations: Available for rotating, oscillating, or stationary conditions

Profiles of VR Lip Seal

Frequently Asked Questions (FAQ) – VR Seals VS Oil Seals

1. What is the main difference between a VR seal and a standard oil seal?

A VR seal features a membrane that is stretched over the support structure, allowing it to move freely and maintain flexibility even when the support section is enlarged. In contrast, an oil seal has the elastomer bonded or vulcanized directly to the support structure. Additionally, VR seals have a reinforced armor design that enables them to withstand pressures up to 150 bar.

2. Can a VR seal be used as a substitute for an oil seal?

Yes, VR seals can replace oil seals, even when the shaft has developed grooves. Special VR seal versions, such as the BSB type, are designed for direct 1-to-1 replacement of oil seals. The sealing lip of the VR seal will contact a different section of the shaft due to its unique construction.

3. What is the maximum working pressure a standard VR seal can handle?

A standard VR seal can typically withstand pressures up to approximately 15 bar, depending on factors like shaft finish, rotational speed, and temperature. For lower pressures and greater shaft misalignment, a version rated for up to about 6 bar is available.

4. Are there VR seals suitable for high-pressure applications?

Yes, special high-pressure VR seals can withstand up to 150 bar at speeds of 3,000 rpm. These seals feature a precision support ring construction, allowing only a 0.02 mm gap from the shaft to prevent extrusion of the elastomer. The support ring, often made from plain bearing bronze, also functions as a bearing surface.

5. What materials are used for the support struts in VR seals?

Most commonly, the struts are made from stainless steel 304. However, other material options like aluminum, bronze, and acid-resistant stainless steel are also available.

6. What types of single-lip VR seals are offered?

Single-lip VR seals are available in multiple designs depending on the installation position, pressure direction, and mounting configuration.

7. What types of double-lip VR seals are available?

Double-lip VR seals are also offered in various versions tailored to installation requirements, direction of pressure, and assembly method.

8. How important is the shaft surface for VR seal performance?

The shaft surface plays a crucial role in sealing efficiency, especially at high speeds and under pressure. An overly smooth shaft hinders the formation of a lubricating film, increasing wear and heat. A rough shaft, on the other hand, can cause oil leakage and accelerated seal wear.

9. What is the recommended surface roughness of the shaft for VR seals?

For general applications, the shaft should have a surface roughness of Ra = 0.6–0.8 μm in the sealing area. In high-pressure conditions, the recommended roughness is Ra = 0.4–0.6 μm.

10. What shaft and housing tolerances are required for VR seals?

Shafts sealed with VR seals should adhere to the h11 tolerance grade, while the housing bore should comply with the H8 tolerance.

11. Should VR lip seals be lubricated during assembly?

Yes, proper lubrication helps ensure optimal sealing and minimizes wear. For double-lip seals, the cavity between the lips can hold grease, preventing dry operation. Mineral or silicone-based greases are preferred, depending on elastomer compatibility.

12. What type of grease should be used with VR seals?

Use greases with NLGI class 1 or 2 per DIN 51818. For EPDM elastomers, only silicone-based grease is suitable. Avoid synthetic components unless the material is compatible.

13. What is the proper way to assemble a VR lip seal?

Correct assembly significantly affects the lifespan of the seal. The shaft should have a 30° chamfered lead-in taper to help stretch the seal’s inner diameter. Both the shaft and the sealing lip should be lubricated before assembly to ensure smooth run-in and avoid damage.

14. What is the stick-slip effect, and how does it affect VR seals?

Stick-slip occurs when the elastomer sticks to the shaft due to inadequate lubrication. This leads to high resistance when motion begins, potentially damaging the rubber and causing leakage. The material of the support ring influences how severe this effect is.

Let’s Help You Find the Right VR Seal

Every industry has unique challenges. Whether you need food-grade, explosion-proof, or ultra-high-speed seals, CV Technik’s engineering team is ready to help.

Get in touch today to select the optimal seal for your application or request a custom solution.