Fabric Reinforced Oil Seal

Description of Fabric Reinforced Oil Seal

Fabric-reinforced oil seals are advanced sealing solutions designed to withstand high pressures, extreme temperatures, and challenging operating conditions. Unlike traditional seals, they incorporate fabric reinforcement layers along with elastomeric materials, providing enhanced durability and resilience.

Function and Working Fabric Reinforced Oil Seal

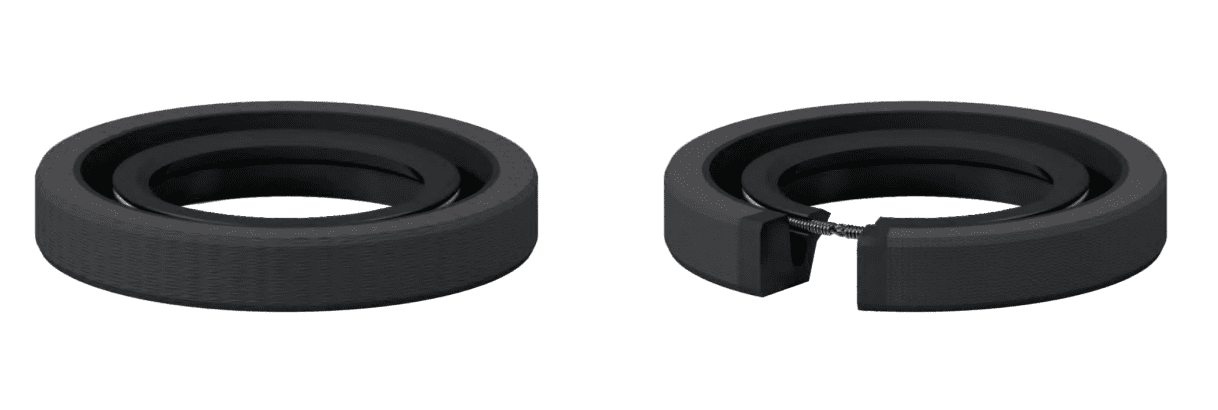

The Standard fabric-reinforced seals are widely used in heavy machinery and engineering industries such as Rolling Mills, Gear Boxes, etc. The material generally used is NBR (Nitrile) / FKM for the sealing lip which is bonded on the outer body made from a hard and rigid fabric reinforced with NBR/FKM. They are used as a viable option to replace metal case oil seals in the field because the proper installation tools for metal case oil seals are not readily available. Since fabric-reinforced seals are not made of metal, concerns about rust and damage are eliminated. Damage during installation is avoided, and the composite material acts as a gasket-type seal and is effective when the bore is worn. Nonmetallic construction also allows for the seal to be split (Straight Cut/Oblique cut), if required. Split versions of fabric-reinforced seals include a hook and eye spring, which can be disassembled and reassembled during installation. To ensure effective sealing at the split ends, a full rubber section is molded at the split ends so that contact between homogeneous elastic surfaces maximizes the sealing effect. Solid versions of fabric-reinforced seals have a fully threaded spring that can be removed altogether if needed. This seal also proves the most cost-effective when compared to other types of seals.

This video from the SKF group explains the various applications and industries where fabric-reinforced oil seals can be used.

Advantages of Fabric Reinforced Oil Seal

No rusting issue

Damage during installation is avoided

Also acts as a gasket-type seal

Available in split-type

Excellent resistance to extreme temperatures

High Durability

Suitable for extreme environment

Reduced Maintenance Costs

Heavy duty applications

Applications of Fabric Reinforced Oil Seal

Steel Manufacturing

Power Plants / Power Generation

Mining and Construction Equipment

Agricultural Machinery

Marine and Offshore Equipment

Railway and Transportation

Oil and Gas Industry

Automotive

Fabric Reinforced Oil Seal Application Industries

-

Hot rolled or cold rolled steel rolling mills

-

Railway and Transportation

-

Marine and Offshore Equipment

-

Construction Equipments and Off-road Vehicles

Product Features of Fabric Reinforced Oil Seal

Heavy Duty sealing application

Pressure up to 0.5 to 10 Bar

Shaft speed up to 10 - 25 m/s

Materials Fabric + NBR / FKM / HNBR / EPDM / Silicone or VMQ

Temperature range -40°C to 220°C

Various profiles are available for different applications