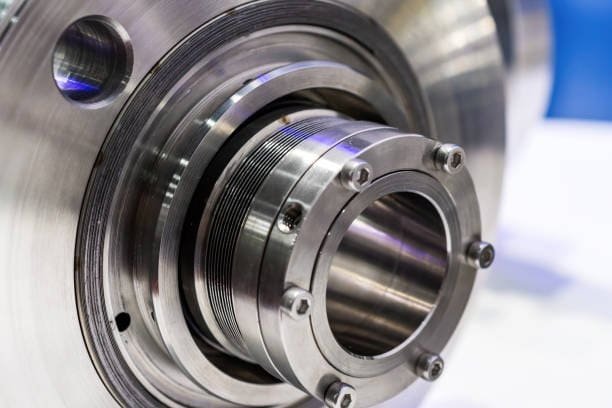

Oil Seal

Description of Oil Seal

One of the most frequently used types of seal is the oil seal also know as Rotary Shaft Seal. This is generally used for sealing lubricating oil or grease in rotary shaft applications. For trouble-free operation and optimum service life of a seal, shafts must have a satisfactory surface finish, within recommended limits and have no machine lay. Both correct design and material choice are critical if bearings and gears are to be sealed to prevent leakage.

Function and Working Principle of Oil Seal

The area between the sealing edge and the shaft is the most important. The sealing effect is obtained by preloading the sealing lip, making its inner diameter slightly smaller than the diameter of the shaft. The garter spring ensures constant mechanical pressure and maintains the radial force on the shaft and extends the sealing edge to the defined width. Sealing is guaranteed by the surface tension of the hydrodynamic oil film between the flattened area of the seal and the shaft. The meniscus acts as an interface between the outside air and the fluid. Any rupture of the meniscus will cause a leak. This can occur if the shaft contains scratches along the path of the joint.

This video from the SKF group explains the working principle and functionality of shaft seal, oil seal, or radial shaft seal.

Advantages of Oil Seal

Oil seals are cost-effective sealing solutions.

Prevent the entry of foreign contaminants.

Maintain lubricity of the system.

Oil seals are easily available in the aftermarket.

A wide dimensional range of oil seals helps for various industrial applications.

Oil seals are available in standard and non-standard materials.

Oil seals are easy to install.

Oil seals have good reliability and sealing performance for standard applications.

Applications of Oil Seal

Usually, oil seals are used to seal lubricating oil or grease, so that moving parts are continuously supplied with enough lubrication. However, such seals are also used for sealing other liquids, gases, and solids, such as powders or granules. Some examples of oil seal applications include:

Electric motors

Gearboxes

Hydraulic Press / Machines

Paper rolls

Industrial pumps and fans

Customized equipment

Conveyors

Elevators

Engines

Grinding Mills

Pipelines

Wind Turbines

Oil Seal Application Industries

-

Automotive Industry

-

Steel and Heavy Engineering

-

Pumps, Motors and Gearboxes

-

Machine Tools Industry

Product Features of Oil Seal

Standard sealing application

Pressure up to 0.5 Bar

Shaft speed up to 10 m/s

Oil seal materials NBR / FKM / HNBR / EPDM / Silicone or VMQ

Temperature range -40°C to 220°C

Cost-effective solution